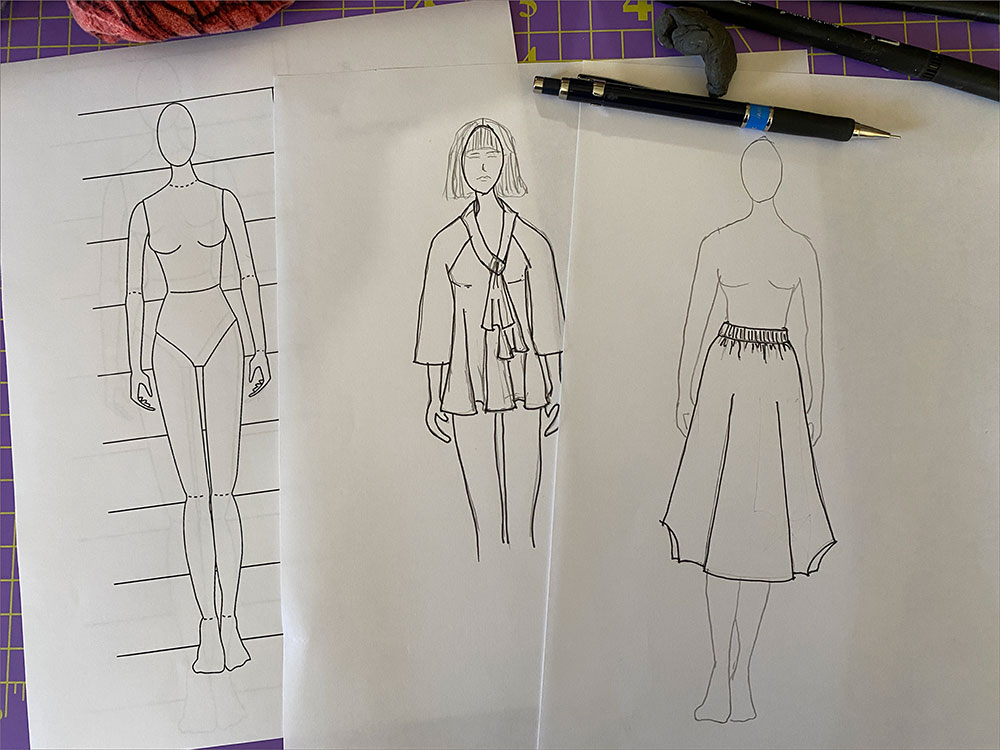

Unlock Your Creativity: Using a Croquis to Design Unique Garments

You don’t need a lot of art training to design or draw your concepts for a new garment. Mostly it takes a little practice and choosing the right aids to assist in the process. This is where the fashion croquis...Read More